Foam Filled Fender

General Details

Foam Filled Fender is versatile, robust and suitable for almost all applications. The manufacturing process allows for virtually any size of fender to be constructed and selecting the appropriate grade of foam core and elastomeric skin means the performance of a fender can be precisely gauged to meet specific specification requirements. Characteristically Foam Filled Fenders have a high energy absorption compared to their reactive load meaning they are ideal for existing structures and certain hull types such as catamarans and cruise ships.

OKIN Foam Filled Fender is a kind of constructive fender with polyurea materials as its outer protective layer and EVA foam core forming the resilient inner part.

The Foam Filled Fenders are constructed of three parts each providing an important function in the construction and lifespan of the fender. The three parts are (1) The closed cell EVA foam. (2) Outer rubber + nylon cord fabrics. (3) Polyurea spraying coat.

(1) Foam Core

The closed cell EVA foam core used inside offers un-sink ability during operation.

(2) Outer Rubber + Nylon Cord Fabrics

The outer rubber + nylon cord fabrics is specifically designed to seal EVA foam inside and to prevent any leakage.

(3) Polyurea Spraying Coating

Polyurea coating is permanent spray on coatings that protect the surface of fender body. It is more durable than rubber and flexible in all weather conditions; no softening in heat or becoming brittle in cold.

Specification

OKIN Foam Filled Fender Specification

| Nominal size | Initial internal pressure | At 60% deflection | Fender body weight (±3%) | |

| Diameter × length | Energy absorption | Reaction force | ||

| mm | kPa | kJ | kN | kgs |

| 300 x 500 | 50 | 43 | 5 | 7 |

| 400 x 800 | 50 | 54 | 7 | 17 |

| 500 × 1000 | 50 | 89 | 32 | 23 |

| 700 × 1500 | 50 | 129 | 24 | 85 |

| 1000 × 1500 | 50 | 190 | 62 | 175 |

| 1000 × 2000 | 50 | 298 | 80 | 240 |

| 1200 × 2000 | 50 | 335 | 110 | 350 |

| 1350 × 2500 | 50 | 460 | 173 | 550 |

| 1500 × 3000 | 50 | 615 | 263 | 770 |

| 1700 × 3000 | 50 | 678 | 330 | 1075 |

| 2000 × 3500 | 50 | 940 | 535 | 1530 |

| 2000 × 4000 | 50 | 1095 | 630 | 1980 |

| 2000 × 4500 | 50 | 1250 | 690 | 2500 |

| 2300 × 4000 | 50 | 1380 | 735 | 2885 |

| 2300 × 5500 | 50 | 1860 | 1133 | 3480 |

| 2500 × 4000 | 50 | 1455 | 980 | 3390 |

| 2500 × 5500 | 50 | 1960 | 1230 | 3985 |

| 3000 × 5000 | 50 | 2180 | 1755 | 5350 |

| 3000 x 6000 | 50 | 2455 | 1960 | 6680 |

| 3300 x 4500 | 50 | 1960 | 1760 | 5750 |

| 3300 x 6500 | 50 | 3075 | 2830 | 8400 |

| 3500 x 7000 | 50 | 3975 | 3162 | 10100 |

-

Marine Fender

-

Super Cell Fender

-

Cone Type Fender

-

Super Arch Rubber Fender

-

Cylindrical Type Fender

-

GD Type Rubber Fender

-

D Type Rubber Fender

-

Square Rubber Fender

-

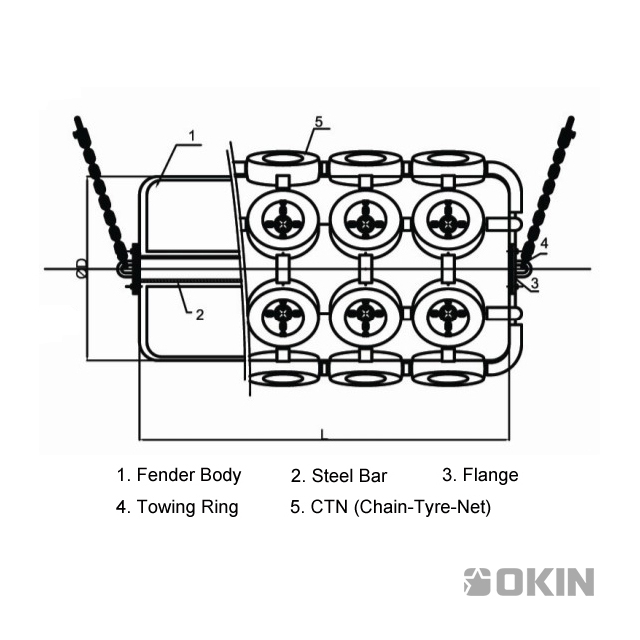

Roller Wheel Fender

-

Tugboat Rubber Fender

-

W Type Rubber Fender

-

Ladder Fender

-

Keyhole Fender

-

Corner Fender

-

Unit Element Fender

-

II Type Fender

-

DA Rubber Fender

-

-

Floating Rubber Fender

-

Dock & Harbour Accessories