D Type Rubber Fender

General Details

D Fender can be pre-curved, chamfered and drilled to aid installation at a relatively low cost and can also be cut to the length required.

OKIN D Fender

D Fenders provide an excellent barrier against damage from all sizes and shapes of vessels. They are ideal for smaller quays and wharves serving fishing boats, tugs, barges and other work craft. D Fenders are also commonly used on pontoons and on inland waterways for lock protection. The flat rear face of D fender makes them easy to install with a flat bar down the bore. OKIN D fenders can be supplied in long lengths with maximum length restricted only by transport and handling limitations.

D Fenders are also called Extrusion Fenders. Extrusion is a manufacturing process involving pushing unvulcanized rubber through a special die to form a constant cross-section profile. This is a simple and cost effective production method for smaller fenders and allows sections to be made in very long lengths. Special profiles can also be produced economically to customer’s specific requirements.

Core Attributes

- Ideal for smaller quays and wharves

- Easy to install with a flat bar down the bore

- Can be supplied in long lengths and be cut to length, angle cut at the ends

Applications

- Smaller jetties and wharves

- Workboats and service craft

- Mooring pontoon protection

- Inland waterways

- General purpose applications

Specification

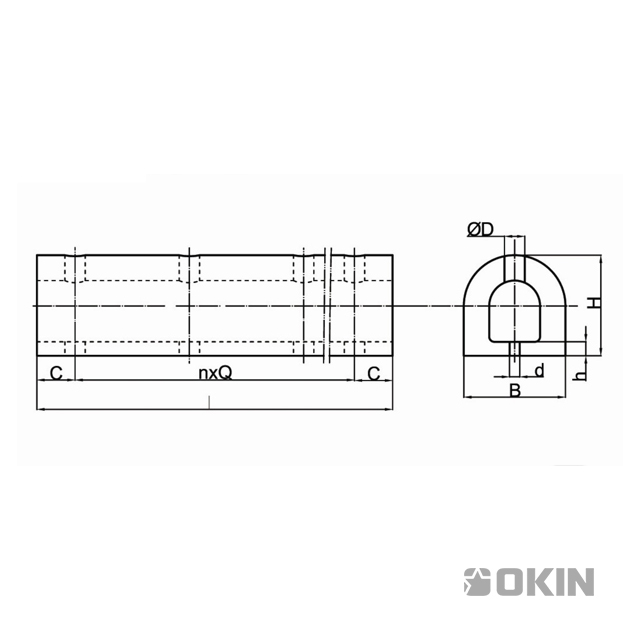

OKIN D Type Fender Specification

| Size | Dimensions (mm) | ||||||||

| (mm) | H | B | L | Holes | Q | C | h | D | d |

| KD150x150x1000L | 150 | 150 | 1000 | 3 | 350 | 150 | 25 | 40 | 24 |

| KD200x200x1000L | 200 | 200 | 1000 | 3 | 350 | 150 | 35 | 55 | 30 |

| KD200x200x3000L | 200 | 200 | 3000 | 8 | 400 | 100 | 35 | 55 | 30 |

| KD250x250x1000L | 250 | 250 | 1000 | 3 | 350 | 150 | 35 | 60 | 30 |

| KD250x250x3000L | 250 | 250 | 3000 | 8 | 400 | 100 | 35 | 60 | 30 |

| KD300x300x1000L | 300 | 300 | 1000 | 3 | 350 | 150 | 40 | 65 | 32 |

| KD300x300x3000L | 300 | 300 | 3000 | 8 | 400 | 100 | 40 | 65 | 32 |

| KD300x360x1000L | 300 | 360 | 1000 | 3 | 350 | 150 | 40 | 65 | 32 |

| KD300x360x3000L | 300 | 360 | 3000 | 8 | 400 | 100 | 40 | 65 | 40 |

| KD400x400x1000L | 400 | 400 | 1000 | 3 | 350 | 150 | 55 | 80 | 32 |

| KD400x400x3000L | 400 | 400 | 3000 | 8 | 400 | 100 | 55 | 80 | 40 |

| KD500x500x1000L | 500 | 500 | 1000 | 3 | 350 | 150 | 90 | 97 | 45 |

| KD500x500x3000L | 500 | 500 | 3000 | 8 | 400 | ||||

-

Marine Fender

-

Super Cell Fender

-

Cone Type Fender

-

Super Arch Rubber Fender

-

Cylindrical Type Fender

-

GD Type Rubber Fender

-

D Type Rubber Fender

-

Square Rubber Fender

-

Roller Wheel Fender

-

Tugboat Rubber Fender

-

W Type Rubber Fender

-

Ladder Fender

-

Keyhole Fender

-

Corner Fender

-

Unit Element Fender

-

II Type Fender

-

DA Rubber Fender

-

-

Floating Rubber Fender

-

Dock & Harbour Accessories